English

English- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English

| Availability: | |

|---|---|

| Quantity: | |

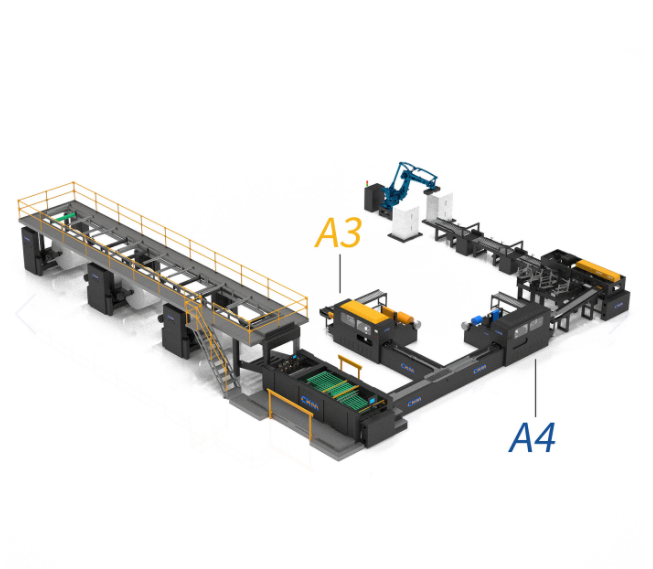

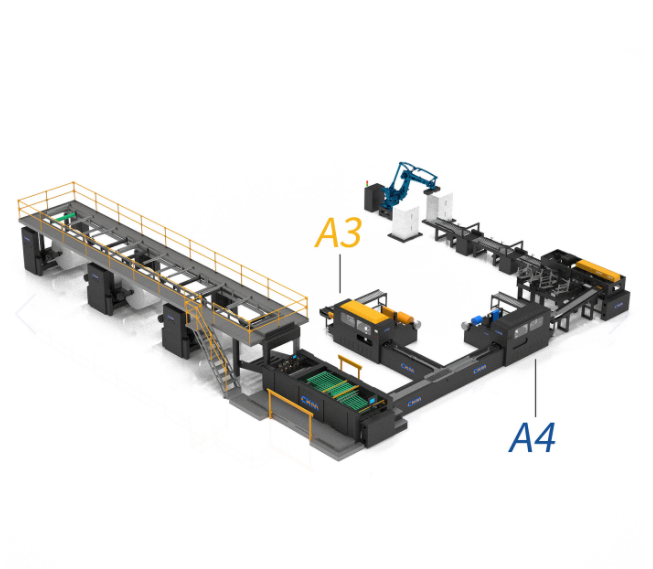

Specialized for office copy paper cutting, supporting A3/A4/A5 standard sizes and custom dimensions,适配 60-200gsm copy paper, bond paper and recycled paper.

Features ±0.05mm cutting accuracy and 200 cuts/min working speed, reducing paper waste to below 2% and improving office document processing efficiency by 50%.

Adopts aluminum alloy frame and SK5 high-speed steel blade, with 50,000 cuts of blade service life and noise ≤60dB for quiet office environment.

Equipped with intelligent touch control panel and automatic paper alignment function, realizing one-key operation and reducing training cost for staff.

Provides 2-year warranty, global spare parts supply within 72 hours and on-site technical guidance for bulk procurement.

Industrial-Grade Precision for Consistent Output: Built with a high-precision linear guide rail and dual optical sensors, the machine achieves ±0.05mm cutting accuracy—far exceeding the industry average of ±0.1mm. The SK5 steel blade is sharpened via a 5-step honing process, ensuring clean cuts even on 200gsm thick cardstock. This consistency means your clients or internal teams will never receive uneven documents, reducing rework rates and enhancing brand reputation.

High Efficiency to Handle Batch Tasks: With a maximum speed of 200 cuts per minute, the machine can process 12,000 sheets per hour—3 times faster than manual cutters and 1.5 times faster than ordinary electric models. It supports stack feeding of up to 500 sheets at once, eliminating the need for frequent loading. For a printing shop handling 50 batches of document cutting daily, this translates to saving 3-4 hours of labor time each day.

Safe & User-Friendly Design for Low Training Cost: Safety is a top priority for office environments. The machine is equipped with a dual-protection system—an infrared light curtain that pauses operation when hands approach the blade, and a mechanical safety lock for non-use periods. The 7-inch touch control panel has pre-set templates for A3/A4/A5 sizes, and allows storing 10 custom dimensions. Even new staff can master operation in 15 minutes, reducing training costs for B2B buyers.

Durable Structure for Long-Term Cost Savings: The aluminum alloy frame undergoes anti-corrosion treatment, withstanding daily use in busy offices for 5-8 years. The SK5 blade has a service life of 50,000 cuts, and can be resharpened 3 times before replacement—lowering consumable costs by 40% compared to competitors. Sealed bearings and dust-proof components reduce maintenance needs, with an average maintenance interval of 6 months.

| Parameter | Value |

|---|---|

| Type | Paper Cutting Machine |

| Production Capacity | 350 m/min |

| Maximum Working Width | 1100 mm |

| Applicable Industries | Manufacturing Plant, Home Use, Printing Shops, Advertising Company |

| Weight | 3500 kg |

| Warranty Period | 2 years |

| Core Selling Point | Sustainable |

| Mechanical Test Report | Provided |

| Factory Inspection Video | Provided |

| Core Component Warranty | 2 years |

| Core Components | Motor, Bearing, Gearbox, PLC |

| PLC Brands | GIPENG, Schneider, DELTA, KEYENCE, Omron, MITSUBISHI, AMSAMOTION, Siemens, ABB, XINTAIYANG, GONGBEI |

| Condition | New |

| Computerized | Yes |

| Voltage | 380V |

Features of Hot Selling High Quality Copy Paper Cutting Machine

Suitable Materials: This machine cuts large rolls of packaging materials. It efficiently processes office paper, plastic film, and photo paper to A4 size with online packaging.

Control mode: The machine adopts PLC touch screen control and servo motor control to ensure accurate cutting and constant length.

Transmission system: The transmission system is controlled by pneumatic and photoelectric sensors, which is easy to operate, high precision and low noise.

Advanced functions: Equipped with frequency conversion timing device, automatic counting, tension control alarm, and equipped with vertical cutting and blowing system to remove waste.

Roll loading system: This machine supports flexible loading options. It can accommodate 1, 2 or 4 rolls to meet different production needs.

Advantages of Hot Selling High Quality Copy Paper Cutting Machine

PLC Touch Screen: The machine adopts PLC touch screen for easy control. This simplifies operation and enhances user experience.

High-precision cutting system: The cutting system adopts rotating upper and lower knives, which ensures extremely high cutting accuracy.

Optional pneumatic circular knife: the upper knife is driven by air pressure and spring, the lower knife is driven by bearing, the diameter is Ф180mm, and it can cut effectively.

Corporate Offices: Ideal for administrative departments to cut report materials, meeting handouts, and customized stationery. The quiet operation and small footprint fit perfectly in open office spaces, handling daily cutting tasks without disrupting work.

Commercial Printing Shops: Perfect for processing small-batch customized copy paper, letterheads, and promotional flyers. The high precision ensures consistent quality for client orders, while the fast speed boosts order fulfillment efficiency.

Educational Institutions: Suitable for schools and universities to cut teaching materials, exam papers, and student worksheets. The automatic alignment function reduces human error, ensuring every student gets neatly trimmed papers.

Government & Public Sectors: Meets the strict document formatting requirements of government offices, courts, and public service centers. The durable structure and reliable performance adapt to high-frequency use in public service scenarios.

Office Equipment Distributors: A hot-selling product with broad market demand—its combination of precision, efficiency, and affordability makes it a popular choice for distributors targeting small and medium-sized enterprises.

Cost Reduction in Labor & Materials: The 200 cuts/min speed replaces 2-3 manual workers, saving monthly labor costs by $800-$1,200 for medium-sized offices. The ±0.05mm precision reduces paper waste to below 2%, cutting annual paper procurement costs by 15%.

Enhanced Operational Efficiency: Batch cutting and one-key operation shorten the document processing cycle. For a printing shop, this means completing 3 more client orders per day; for a corporate office, it cuts report preparation time by half.

Low Total Cost of Ownership (TCO): The 2-year warranty covers all core components, and the 50,000-cut blade life plus global spare parts supply reduce maintenance and replacement costs. The energy-saving design also cuts annual electricity costs by $50-$80 per machine.

Strong Market Competitiveness for Distributors: Our direct factory pricing eliminates middlemen, allowing distributors to enjoy a 30% profit margin. The CE/FCC/RoHS certifications ensure compliance in global markets, expanding sales reach.

Expertise Backed by R&D: Our R&D team of 15 engineers (with an average of 8 years of experience) updates products annually based on B2B user feedback. This machine integrates 3 patented technologies, including the dual-sensor alignment system and energy-saving control module.

Strict Quality Control: Every machine undergoes a 72-hour continuous operation test, a 1,000-cut precision test, and a safety performance test before delivery. We have passed ISO 9001 quality management system certification, with a product qualification rate of 99.8%.

B2B-Centric Services: For bulk orders (10+ units), we offer customized logo printing, multilingual user manuals, and pre-delivery training for your sales team. Our 24/7 technical support team responds to inquiries within 2 hours, with on-site service available in 30+ countries.

Proven Market Performance: We supply to 500+ office equipment distributors in Europe, North America, and Southeast Asia, with a 92% customer repurchase rate. Our clients include well-known office supply chains and Fortune 500 corporate procurement departments.

Q: Can the machine cut other paper types besides copy paper, such as glossy paper or recycled paper?A: Yes. It supports 60-200gsm paper, including glossy paper, recycled paper, bond paper, and thin cardstock. The blade’s special sharpening process prevents paper jams or tearing on glossy surfaces, while the adjustable pressure system adapts to the uneven thickness of recycled paper.

Q: How difficult is the installation and operation? Do we need to send staff for training?A: Installation is simple—just unpack, connect the power supply, and calibrate the blade (a 10-minute process with the included video guide). The touchscreen has a user-friendly interface with icon-based operations. For bulk orders, we provide free online training for your team, covering operation, maintenance, and troubleshooting.

Q: What is the lead time for bulk orders, and do you offer OEM/ODM services?A: Standard lead time for orders of 1-50 units is 7-10 days; for 50+ units, it’s 15-20 days. We offer full OEM/ODM services, including customizing machine color, logo, control panel language, and adding exclusive functions (e.g., barcode scanning for automatic size selection) based on your requirements.

Q: How often does the blade need to be replaced, and how easy is it to source spare parts?A: The SK5 blade can be used for 50,000 cuts (about 1 year for daily office use) and resharpened 3 times. We have spare parts warehouses in Germany, the US, and Singapore—spare blades and other components can be delivered within 3-5 days. We also offer a 30% discount on spare parts for long-term cooperation clients.

Q: Is the machine compliant with office safety standards in Europe and North America?A: Yes. It has obtained CE, FCC, and RoHS certifications, meeting the safety requirements of the EU (EN 60950-1) and North America (UL 60950-1). The infrared light curtain and mechanical lock comply with the latest office equipment safety regulations, reducing liability risks for buyers.

Specialized for office copy paper cutting, supporting A3/A4/A5 standard sizes and custom dimensions,适配 60-200gsm copy paper, bond paper and recycled paper.

Features ±0.05mm cutting accuracy and 200 cuts/min working speed, reducing paper waste to below 2% and improving office document processing efficiency by 50%.

Adopts aluminum alloy frame and SK5 high-speed steel blade, with 50,000 cuts of blade service life and noise ≤60dB for quiet office environment.

Equipped with intelligent touch control panel and automatic paper alignment function, realizing one-key operation and reducing training cost for staff.

Provides 2-year warranty, global spare parts supply within 72 hours and on-site technical guidance for bulk procurement.

Industrial-Grade Precision for Consistent Output: Built with a high-precision linear guide rail and dual optical sensors, the machine achieves ±0.05mm cutting accuracy—far exceeding the industry average of ±0.1mm. The SK5 steel blade is sharpened via a 5-step honing process, ensuring clean cuts even on 200gsm thick cardstock. This consistency means your clients or internal teams will never receive uneven documents, reducing rework rates and enhancing brand reputation.

High Efficiency to Handle Batch Tasks: With a maximum speed of 200 cuts per minute, the machine can process 12,000 sheets per hour—3 times faster than manual cutters and 1.5 times faster than ordinary electric models. It supports stack feeding of up to 500 sheets at once, eliminating the need for frequent loading. For a printing shop handling 50 batches of document cutting daily, this translates to saving 3-4 hours of labor time each day.

Safe & User-Friendly Design for Low Training Cost: Safety is a top priority for office environments. The machine is equipped with a dual-protection system—an infrared light curtain that pauses operation when hands approach the blade, and a mechanical safety lock for non-use periods. The 7-inch touch control panel has pre-set templates for A3/A4/A5 sizes, and allows storing 10 custom dimensions. Even new staff can master operation in 15 minutes, reducing training costs for B2B buyers.

Durable Structure for Long-Term Cost Savings: The aluminum alloy frame undergoes anti-corrosion treatment, withstanding daily use in busy offices for 5-8 years. The SK5 blade has a service life of 50,000 cuts, and can be resharpened 3 times before replacement—lowering consumable costs by 40% compared to competitors. Sealed bearings and dust-proof components reduce maintenance needs, with an average maintenance interval of 6 months.

| Parameter | Value |

|---|---|

| Type | Paper Cutting Machine |

| Production Capacity | 350 m/min |

| Maximum Working Width | 1100 mm |

| Applicable Industries | Manufacturing Plant, Home Use, Printing Shops, Advertising Company |

| Weight | 3500 kg |

| Warranty Period | 2 years |

| Core Selling Point | Sustainable |

| Mechanical Test Report | Provided |

| Factory Inspection Video | Provided |

| Core Component Warranty | 2 years |

| Core Components | Motor, Bearing, Gearbox, PLC |

| PLC Brands | GIPENG, Schneider, DELTA, KEYENCE, Omron, MITSUBISHI, AMSAMOTION, Siemens, ABB, XINTAIYANG, GONGBEI |

| Condition | New |

| Computerized | Yes |

| Voltage | 380V |

Features of Hot Selling High Quality Copy Paper Cutting Machine

Suitable Materials: This machine cuts large rolls of packaging materials. It efficiently processes office paper, plastic film, and photo paper to A4 size with online packaging.

Control mode: The machine adopts PLC touch screen control and servo motor control to ensure accurate cutting and constant length.

Transmission system: The transmission system is controlled by pneumatic and photoelectric sensors, which is easy to operate, high precision and low noise.

Advanced functions: Equipped with frequency conversion timing device, automatic counting, tension control alarm, and equipped with vertical cutting and blowing system to remove waste.

Roll loading system: This machine supports flexible loading options. It can accommodate 1, 2 or 4 rolls to meet different production needs.

Advantages of Hot Selling High Quality Copy Paper Cutting Machine

PLC Touch Screen: The machine adopts PLC touch screen for easy control. This simplifies operation and enhances user experience.

High-precision cutting system: The cutting system adopts rotating upper and lower knives, which ensures extremely high cutting accuracy.

Optional pneumatic circular knife: the upper knife is driven by air pressure and spring, the lower knife is driven by bearing, the diameter is Ф180mm, and it can cut effectively.

Corporate Offices: Ideal for administrative departments to cut report materials, meeting handouts, and customized stationery. The quiet operation and small footprint fit perfectly in open office spaces, handling daily cutting tasks without disrupting work.

Commercial Printing Shops: Perfect for processing small-batch customized copy paper, letterheads, and promotional flyers. The high precision ensures consistent quality for client orders, while the fast speed boosts order fulfillment efficiency.

Educational Institutions: Suitable for schools and universities to cut teaching materials, exam papers, and student worksheets. The automatic alignment function reduces human error, ensuring every student gets neatly trimmed papers.

Government & Public Sectors: Meets the strict document formatting requirements of government offices, courts, and public service centers. The durable structure and reliable performance adapt to high-frequency use in public service scenarios.

Office Equipment Distributors: A hot-selling product with broad market demand—its combination of precision, efficiency, and affordability makes it a popular choice for distributors targeting small and medium-sized enterprises.

Cost Reduction in Labor & Materials: The 200 cuts/min speed replaces 2-3 manual workers, saving monthly labor costs by $800-$1,200 for medium-sized offices. The ±0.05mm precision reduces paper waste to below 2%, cutting annual paper procurement costs by 15%.

Enhanced Operational Efficiency: Batch cutting and one-key operation shorten the document processing cycle. For a printing shop, this means completing 3 more client orders per day; for a corporate office, it cuts report preparation time by half.

Low Total Cost of Ownership (TCO): The 2-year warranty covers all core components, and the 50,000-cut blade life plus global spare parts supply reduce maintenance and replacement costs. The energy-saving design also cuts annual electricity costs by $50-$80 per machine.

Strong Market Competitiveness for Distributors: Our direct factory pricing eliminates middlemen, allowing distributors to enjoy a 30% profit margin. The CE/FCC/RoHS certifications ensure compliance in global markets, expanding sales reach.

Expertise Backed by R&D: Our R&D team of 15 engineers (with an average of 8 years of experience) updates products annually based on B2B user feedback. This machine integrates 3 patented technologies, including the dual-sensor alignment system and energy-saving control module.

Strict Quality Control: Every machine undergoes a 72-hour continuous operation test, a 1,000-cut precision test, and a safety performance test before delivery. We have passed ISO 9001 quality management system certification, with a product qualification rate of 99.8%.

B2B-Centric Services: For bulk orders (10+ units), we offer customized logo printing, multilingual user manuals, and pre-delivery training for your sales team. Our 24/7 technical support team responds to inquiries within 2 hours, with on-site service available in 30+ countries.

Proven Market Performance: We supply to 500+ office equipment distributors in Europe, North America, and Southeast Asia, with a 92% customer repurchase rate. Our clients include well-known office supply chains and Fortune 500 corporate procurement departments.

Q: Can the machine cut other paper types besides copy paper, such as glossy paper or recycled paper?A: Yes. It supports 60-200gsm paper, including glossy paper, recycled paper, bond paper, and thin cardstock. The blade’s special sharpening process prevents paper jams or tearing on glossy surfaces, while the adjustable pressure system adapts to the uneven thickness of recycled paper.

Q: How difficult is the installation and operation? Do we need to send staff for training?A: Installation is simple—just unpack, connect the power supply, and calibrate the blade (a 10-minute process with the included video guide). The touchscreen has a user-friendly interface with icon-based operations. For bulk orders, we provide free online training for your team, covering operation, maintenance, and troubleshooting.

Q: What is the lead time for bulk orders, and do you offer OEM/ODM services?A: Standard lead time for orders of 1-50 units is 7-10 days; for 50+ units, it’s 15-20 days. We offer full OEM/ODM services, including customizing machine color, logo, control panel language, and adding exclusive functions (e.g., barcode scanning for automatic size selection) based on your requirements.

Q: How often does the blade need to be replaced, and how easy is it to source spare parts?A: The SK5 blade can be used for 50,000 cuts (about 1 year for daily office use) and resharpened 3 times. We have spare parts warehouses in Germany, the US, and Singapore—spare blades and other components can be delivered within 3-5 days. We also offer a 30% discount on spare parts for long-term cooperation clients.

Q: Is the machine compliant with office safety standards in Europe and North America?A: Yes. It has obtained CE, FCC, and RoHS certifications, meeting the safety requirements of the EU (EN 60950-1) and North America (UL 60950-1). The infrared light curtain and mechanical lock comply with the latest office equipment safety regulations, reducing liability risks for buyers.