English

English- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English

Views: 0 Author: Site Editor Publish Time: 2025-07-31 Origin: Site

When dealing with large rolls of paper, choosing the right machine can make or break your production process. But should you opt for a paper sheeting machine or a slitter rewinder? In this article, we’ll explore both machines, comparing their functions, advantages, and which is best suited for your needs. Whether you’re in printing, packaging, or manufacturing, this comparison is crucial for improving efficiency and reducing waste.

A paper sheeting machine is designed to convert large rolls of paper into individual sheets of specific lengths. It works by unrolling the paper, cutting it to the desired size, and then stacking the sheets for further processing or use. These machines are crucial in industries like printing and packaging, where precise sheets are required for different applications. Paper sheeting machines can process various types of paper, including printing paper, packaging material, and other flexible substrates like nonwovens and laminates. They are commonly used in high-speed production environments where consistent and accurate sheet sizes are essential.

Precision Cutting: The machine offers high precision when cutting paper to exact sheet sizes, ensuring uniformity and reducing material waste.

Versatility: It can handle a variety of materials, from lightweight paper to heavier grades, making it adaptable for different industries.

Best for Individual Sheets: If your production requires sheets, such as for printing, packaging, or specialty papers, a paper sheeting machine is the ideal solution.

Automatic Tension Control: This feature ensures the paper is fed smoothly through the machine without any slack, improving consistency and reducing defects.

Precise Length Measurement: The machine can be set to cut paper to very specific lengths, allowing for flexibility and high customization in production.

High-Speed Cutting: With high-speed cutting capabilities, paper sheeting machines improve production efficiency, helping to meet large-scale demands quickly.

Handling Diverse Materials: These machines can process not just paper, but also materials like nonwovens, laminates, and films, making them versatile for various industries.

A slitter rewinder is a machine designed to convert large parent rolls of paper into narrower rolls of desired widths. It works by unrolling a large paper roll, slitting it into smaller, precise strips, and then rewinding them onto new cores. This process makes it easier to handle and further process paper in industries like printing and packaging. Slitter rewinders can handle various materials beyond paper, including kraft paper, paperboard, films, foils, and other flexible materials. These machines are essential in industries where large rolls need to be resized for specific applications.

Handling Large Rolls: A slitter rewinder is perfect for reducing the size of bulky, large rolls into manageable pieces. This makes it easier to process and transport.

Flexibility in Roll Widths: It can be adjusted to produce different widths of rolls, offering flexibility in production. This is particularly useful in industries that require customized roll sizes.

High-Speed Efficiency: These machines are designed for high-volume production, enabling fast and efficient slitting, which is ideal for large-scale operations where time is critical.

Versatility in Material Handling: Slitter rewinders can process a variety of materials, including kraft, linerboard, films, and foils. This versatility makes them suitable for many applications across different industries.

Automatic Alignment and Tension Control: These machines come equipped with systems that automatically align the material and control tension, ensuring accurate cuts and smooth operation.

Adaptability to Material Properties: Slitter rewinders can be configured to handle materials of different thicknesses and types, making them adaptable to changing production needs.

When to Use a Paper Sheeting Machine: A paper sheeting machine is ideal when you need individual sheets of paper, such as for printing, packaging, or specialty papers. It cuts large rolls into precise sheet sizes required for these industries.

When to Use a Slitter Rewinder: A slitter rewinder is best used for reducing large rolls into narrower rolls that can be further processed. It’s commonly used in commercial printing, packaging, and flexible materials like films and foils.

Cutting Precision: Paper sheeting machines offer high precision in cutting sheets to exact lengths, while slitter rewinders excel in making narrow, consistent rolls. Both are highly precise in their respective tasks.

Customization: Slitter rewinders allow for the adjustment of roll widths, offering flexibility for different production needs. On the other hand, paper sheeting machines provide the ability to adjust sheet sizes, making them more versatile for sheeted paper applications.

Production Speed: Both machines are designed for high-speed operation. However, slitter rewinders excel in large-scale production environments where high-speed roll slitting is necessary, while paper sheeting machines are more focused on cutting specific sheet sizes quickly and efficiently.

Bulk Production: Slitter rewinders are generally better suited for bulk production of narrow rolls, while paper sheeting machines shine in environments where individual sheets are required at high speed.

Paper Types and Thickness: Both machines can handle various paper types, but slitter rewinders are more flexible when it comes to materials like kraft paper, paperboard, and film. Paper sheeting machines can handle a wider range of paper thicknesses and other materials such as nonwovens or laminates, making them versatile in other industries.

Applications for Different Materials: Slitter rewinders are often used in industries requiring consistent rolls, while paper sheeting machines are favored for high-quality sheets needed for printing and packaging.

Slitting: Slitting is a continuous process that reduces the width of a roll of material. This method is ideal for making narrower rolls from large parent rolls.

Cutting: Cutting is used to divide material into discrete sheets or shapes. While slitting focuses on reducing the width, cutting focuses on creating defined, precise lengths.

Paper sheeting machines are ideal for converting large rolls of paper into individual sheets. They are especially useful in industries such as:

Printing: Ensuring high-quality, precise sheets for various printing applications.

Packaging: Producing consistent sheets for packaging materials.

Papermaking: Cutting large rolls into specific sheet sizes for further processing or use. These machines are perfect for applications where precise, sheeted paper is needed, such as specialty papers or luxury packaging.

Printing Houses: Need accurate, high-quality sheets for different printing projects.

Packaging Manufacturers: Require consistent sheets for packaging material production.

Commercial Production: Businesses that need large-scale production of high-quality sheets for various uses will benefit greatly from a paper sheeting machine.

Material Type and Thickness: Make sure the machine can handle the paper or material types and thicknesses you plan to use.

Sheet Size Requirements: The machine should allow you to adjust the sheet sizes according to your production needs.

Speed and Automation: Consider the required production speed and whether automation features, such as tension control or cutting precision, are necessary for your operation.

Slitter rewinders are designed to convert large parent rolls into narrower, more manageable rolls. They are particularly useful in:

Converting Large Parent Rolls: Slitting large rolls into smaller widths to facilitate further processing or packaging.

High-Speed Commercial Printing and Packaging: Ideal for fast-paced environments where large volumes of narrow rolls are required for printing or packaging.

Flexible Materials: Perfect for processing films, foils, and other flexible materials in addition to paper. These machines are essential for industries requiring continuous slitting and rewinding at high speeds.

Commercial Printing: Slitter rewinders help convert large rolls of paper or material into narrower rolls for printing presses.

Packaging: Used in packaging to create specific-sized rolls for labels, wraps, or packaging materials.

Manufacturing: Many industries, including automotive and electronics, need narrow rolls for manufacturing processes.

Tissue, Foil, and Film Industries: These sectors often require precise, narrow rolls for tissue paper, foils, and films, making slitter rewinders an ideal choice.

Roll Width and Core Size Options: Make sure the machine can handle the desired roll width and core size for your production needs.

Customization and Flexibility: Look for a machine that offers adjustable settings, allowing for flexibility in processing different materials and varying roll sizes.

When comparing the prices of paper sheeting machines and slitter rewinders, the initial investment can vary significantly depending on the machine's specifications. Generally, paper sheeting machines tend to have a higher initial cost due to their precision and versatility in handling different sheet sizes and materials. On the other hand, slitter rewinders can be more affordable, especially if the required width adjustments and material handling capabilities are basic. Several factors influence the cost:

Capacity: Larger, high-capacity machines will naturally cost more.

Automation: Machines with advanced automation features, like tension control and automatic alignment, will increase the price.

Material Handling: Machines capable of handling a variety of materials (e.g., nonwovens, films) may come at a premium.

While the initial price is important, operational costs also play a major role in the long-term affordability of each machine. Slitter rewinders are often more cost-efficient in the long run due to their simpler design and fewer maintenance needs. Paper sheeting machines, while precise, may require more frequent maintenance and higher energy consumption due to their complex cutting and handling systems. Key considerations for operational costs include:

Maintenance: Paper sheeting machines tend to require more maintenance than slitter rewinders due to their intricate components.

Material Waste: The precision of paper sheeting machines reduces material waste, which can make them more efficient in high-quality sheet production.

Energy Consumption: Sheeting machines are usually more energy-intensive because of their high-speed cutting mechanisms.

For slitter rewinders, operational costs can be influenced by:

Blade Replacements: Over time, the blades used in slitting wear out and need replacement, adding to ongoing costs.

Machine Setup Adjustments: Frequent adjustments to the roll width or material type can lead to downtime and increased labor costs.

Operator Involvement: Slitter rewinders often require more manual intervention, which can increase labor costs if not automated. To reduce these costs, implementing regular maintenance practices such as blade sharpening, proper machine calibration, and reducing unnecessary machine downtime can significantly improve efficiency and reduce long-term expenses.

For Paper Sheeting Machines:

Blade Wear: Over time, the blades on paper sheeting machines can become dull, leading to less precise cuts and more material waste.

Misalignment: Misalignment of the paper feed or cutting mechanisms can cause uneven cuts and reduce the machine's efficiency.

Feeding Problems: If the paper is not fed correctly into the machine, it can cause jams or inconsistent cutting.

For Slitter Rewinders:

Tension Control: Incorrect tension can lead to uneven slitting and poor-quality rolls, making tension control systems critical to performance.

Misfeeds: The paper or material may not feed properly into the machine, resulting in miscuts and waste.

Blade Calibration: Slitter blades need to be calibrated regularly to ensure consistent cuts and maintain the quality of the rolls.

Paper Sheeting Machines:

Blade Issues: Regularly check the sharpness of the blades. If they are worn, replace them to maintain cutting precision.

Misalignment: Recalibrate the machine’s alignment to ensure that the paper moves straight through the cutting area.

Feeding Issues: Ensure the paper is properly aligned and not overloaded to prevent jams. Clean the feeding area regularly.

Slitter Rewinders:

Tension Problems: Adjust the tension control settings to ensure the material moves smoothly through the machine. Regular calibration of the tension system is key.

Misfeeds: Double-check that the material is correctly aligned and that the feeding mechanism is working efficiently.

Blade Calibration: Periodically check and calibrate the blades to avoid uneven slitting and material waste.

Regular Checks: Perform daily or weekly checks of all machine components, including blades, tension systems, and feeding mechanisms.

Cleaning: Keep the machine clean from dust, paper debris, and other contaminants that can affect performance.

Part Replacements: Replace worn-out parts, such as blades and belts, before they cause major issues.

Maintaining Blade Sharpness: Keeping blades sharp ensures precise cuts and reduces wear on other machine parts.

Tension Calibration: Regular calibration of the tension control system is essential to avoid slitting or feeding issues.

Production Scale: Consider whether you need high-volume production or precision work. Slitter rewinders are better for large-scale, high-speed operations, while paper sheeting machines are ideal when precise sheet sizes are required for smaller production runs.

Material Characteristics: The type, thickness, and length of the paper you'll be working with are key factors. Paper sheeting machines handle a variety of materials, including nonwovens and laminates. Slitter rewinders are best for materials like kraft paper, paperboard, and films that need to be slitted into narrower rolls.

Production Speed and Efficiency: If you’re working in a high-speed environment with large volumes of material, a slitter rewinder is likely a better fit. For more customized work, such as luxury packaging or specialty papers, a paper sheeting machine would be the better choice due to its precision.

Automation and Customization Features: Automation can help speed up production and reduce labor costs. Paper sheeting machines often come with more advanced automation features, including tension control and adjustable sheet sizes. Slitter rewinders can also offer customization, but their focus is on roll widths rather than sheet precision.

Which is the Better Option?:

Choose a paper sheeting machine if you require high-precision sheet production, handle various paper types and thicknesses, and need flexibility for smaller-scale or specialty production runs.

Opt for a slitter rewinder if your needs focus on converting large parent rolls into narrower rolls for high-volume commercial printing, packaging, or flexible material processing.

Ideal Use Cases:

Paper Sheeting Machine: Printing houses, packaging manufacturers, papermaking industries, and high-precision sheet production.

Slitter Rewinder: Commercial printing, large-scale packaging, tissue, foil, and film industries, and any high-speed operation focused on roll conversion.

Recap of Paper Sheeting Machine vs. Slitter Rewinder Comparison: Paper sheeting machines are ideal for precision sheet production, while slitter rewinders excel in high-volume roll conversions. Both machines offer unique advantages depending on production needs.

How to Ensure Your Machine Selection Meets Your Needs: Understand your production scale, material types, and speed requirements to select the right machine for optimal performance.

Future Trends and Technological Advances: Expect advancements in automation, speed, and material handling to improve both machines' efficiency and versatility in the near future.

A1: A paper sheeting machine cuts large rolls into precise sheets, while a slitter rewinder reduces the width of large rolls into narrower rolls for further processing.

A2: Choose a paper sheeting machine if you need precise, sheeted paper for printing or packaging. Opt for a slitter rewinder for high-speed, large-scale operations needing narrower rolls.

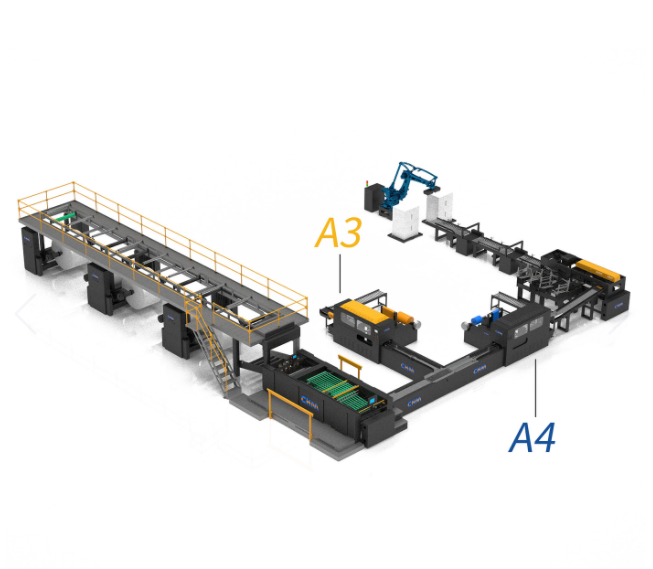

A3: Slitter rewinders are generally more cost-efficient due to their simpler design and lower maintenance needs. Paper sheeting machines may incur higher operational costs but provide more precision.

A4: Paper sheeting machines are more versatile with materials like nonwovens, laminates, and paper. Slitter rewinders excel with materials like kraft paper, paperboard, and films.

A5: Consider production scale, material type and thickness, speed, and automation features. This ensures the machine suits your production line’s specific needs.