English

English- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English

Views: 182 Author: Site Editor Publish Time: 2025-08-23 Origin: Site

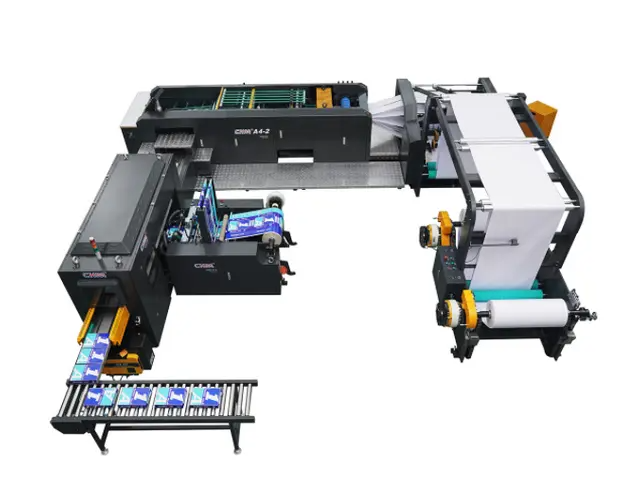

A paper sheeting machine is a vital piece of equipment for converting large rolls of paper into precisely cut sheets for various industries. Whether used in printing, packaging, or specialty applications, its versatility depends largely on the types of paper it can handle. Modern high-precision paper sheeting machines, such as advanced commercial-grade models, are designed to work with a broad range of paper materials, delivering consistent accuracy and efficiency. Understanding the variety of paper types compatible with these machines helps manufacturers, printers, and converters choose the right equipment for their production needs.

One of the key strengths of a paper sheeting machine is its ability to process different paper grades without compromising quality. Unlike older models that were limited to specific paper types, today’s high-precision sheeters integrate advanced cutting systems, tension control, and feeding mechanisms to handle papers of varying thicknesses, textures, and coatings. This adaptability makes them a valuable investment for companies dealing with diverse product lines.

For example, a machine equipped with adjustable cutting speeds, automated tension regulation, and servo-driven control can switch from lightweight tissue paper to heavy-duty board stock in minutes. This flexibility not only saves time but also reduces the need for multiple machines, allowing operators to maximize productivity while maintaining high output quality.

Coated paper is a popular choice for high-end printing and packaging due to its smooth surface and enhanced printability. Paper sheeting machines handle various coated grades, including gloss, matte, and silk finishes. The coating layer, often made of clay or polymer, improves ink absorption and color vibrancy, making these papers ideal for magazines, brochures, and premium packaging.

Processing coated paper requires precise cutting to avoid surface cracking or coating delamination. Advanced sheeters use fine-tuned cutting blades and controlled feed tension to maintain edge sharpness and prevent fiber pull-out. The result is a clean, professional finish that meets the demands of high-quality print applications.

Uncoated paper, such as offset paper, bond paper, and book paper, is widely used for everyday printing, writing, and publishing. It has a natural texture that absorbs ink well, making it suitable for documents, stationery, and books. Paper sheeting machines excel in handling uncoated grades because they offer stable feeding and clean cuts, even at high speeds.

Since uncoated papers are generally more porous and less dense than coated papers, the sheeter must maintain consistent tension to avoid curling or tearing. Modern machines include automated sensors to adjust pressure and blade position based on paper thickness, ensuring each sheet is cut with pinpoint accuracy.

Specialty papers include unique materials such as kraft paper, art paper, synthetic paper, and security paper. These are used for custom packaging, creative projects, labeling, and anti-counterfeiting applications. Paper sheeting machines designed for high precision can process specialty papers without damaging their unique properties.

For instance, synthetic paper, often made from polypropylene or polyester, requires specific blade sharpness to prevent melting or fraying. Similarly, watermark security paper demands precision cutting to maintain design integrity. High-end sheeters can accommodate these needs through customizable cutting programs and specialized feeding systems.

Board materials, such as folding boxboard (FBB), solid bleached sulfate (SBS), and chipboard, are essential for packaging and commercial printing. These heavy, rigid materials require more cutting force, which is why the build quality of a paper sheeting machine matters. Machines with reinforced frames, high-torque motors, and hardened steel blades can easily handle thick board stock while maintaining consistent sheet dimensions.

In packaging industries, precision is critical because improperly cut boards can cause alignment issues in automated packing lines. A commercial-grade paper sheeting machine ensures that every sheet is dimensionally accurate, enhancing downstream efficiency and reducing material waste.

With sustainability becoming a global priority, recycled papers are gaining popularity in printing and packaging. These papers often contain varying fiber lengths and densities, which can make cutting more challenging. A paper sheeting machine with adjustable cutting pressure and blade clearance can handle these variations effectively.

Processing recycled paper also demands attention to dust control, as recycled fibers may produce more debris during cutting. Modern sheeters integrate dust extraction systems to maintain clean cutting zones, improving both product quality and machine longevity.

| Paper Type | Common Applications | Machine Requirements |

|---|---|---|

| Coated Paper | Magazines, brochures, premium packaging | Precision cutting, tension control, anti-crack blade settings |

| Uncoated Paper | Books, stationery, office printing | Consistent tension, adjustable feed pressure, smooth blade operation |

| Specialty Paper | Labels, security documents, creative arts | Custom blade settings, specialty feeding systems, low-heat cutting |

| Board/Cardstock | Folding cartons, commercial print jobs | High cutting force, reinforced structure, hardened steel blades |

| Recycled Paper | Eco-friendly packaging, printing | Adjustable blade clearance, dust control, tension adaptability |

The range of paper types a sheeting machine can handle depends on several factors, including:

Blade Quality: High-carbon or tungsten steel blades extend lifespan and provide cleaner cuts across various paper densities.

Tension Control: Proper web tension prevents curling, tearing, or uneven edges.

Automation Level: Machines with programmable settings can quickly adapt to new paper types, reducing setup time.

Speed and Throughput: High-speed sheeters must maintain precision even when processing lightweight or delicate papers.

Dust and Waste Management: Especially important for recycled or fibrous materials.

By choosing a machine with these features, operators can confidently work with a wide variety of papers without compromising productivity or quality.

Q1: Can one paper sheeting machine handle both thin tissue paper and thick board?

Yes. High-precision commercial sheeters are designed to process a wide range of paper thicknesses, often from 40 gsm tissue paper up to 450 gsm board stock, provided they have adjustable cutting force and tension controls.

Q2: Will coated paper damage the cutting blades over time?

Not if the machine uses hardened steel or tungsten carbide blades. Coated paper may cause slightly more wear due to its surface treatment, but quality blades and proper maintenance will ensure longevity.

Q3: How quickly can a machine switch between different paper types?

With programmable controls and quick-adjust settings, many machines can transition between paper types in under 15 minutes, minimizing downtime.

Q4: Is recycled paper more difficult to sheet?

Yes, due to its variable fiber structure. However, modern sheeters with adjustable pressure and dust extraction handle recycled paper efficiently.

Q5: Are there limitations to specialty paper processing?

Some extremely delicate or heat-sensitive specialty papers may require slower cutting speeds or custom blade configurations, but most commercial sheeters can be adapted for them.

A high-precision commercial paper sheeting machine offers unmatched versatility, capable of handling everything from delicate tissue paper to heavy-duty board stock. Its adaptability makes it an essential asset for printers, converters, and packaging manufacturers seeking efficiency and quality. By understanding the range of paper types these machines can process—coated, uncoated, specialty, board, and recycled—businesses can make informed investment decisions that align with their production goals. With the right configuration, one machine can serve multiple applications, reducing costs while expanding production capabilities.