English

English- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English

Views: 0 Author: Site Editor Publish Time: 2025-10-20 Origin: Site

Ever wondered how large rolls of paper transform into neat sheets? Enter the paper sheeter machine, a crucial tool for industries like printing and packaging. These machines ensure precision and efficiency in cutting paper rolls into uniform sheets. In this post, you'll learn about the types of papers suitable for paper sheeter machines and their significance in various industries.

A paper sheeter machine is a device designed to cut large rolls of paper into sheets of specific sizes. It transforms continuous paper rolls into manageable, uniform sheets ready for further processing or packaging. The machine works by feeding the paper roll through rollers and cutting it precisely using blades or rotary cutters. This process ensures consistent sheet dimensions, which is crucial for industries like printing, packaging, and stationery manufacturing.

Paper sheeter machines come in various types, each suited for different production needs:

● Manual Sheeters: Operated by hand, suitable for low-volume or small-scale applications. They offer basic functionality and are cost-effective but require more labor.

● Semi-Automatic Sheeters: Combine manual feeding with automated cutting. These machines improve efficiency and accuracy compared to manual versions.

● Fully Automatic Sheeters: Feature automated feeding, cutting, stacking, and sometimes packaging. They are designed for high-volume production with minimal human intervention.

● High-Speed Sheeters: Specialized automatic machines that operate at very high cutting speeds, ideal for large-scale industrial use.

● Specialty Sheeters: Customized machines designed to handle unique paper types or sizes, such as corrugated board or synthetic sheets.

Modern paper sheeter machines incorporate advanced technologies to enhance performance:

● Servo Motor Control: Provides precise control over paper feeding and cutting speeds, improving accuracy and reducing waste.

● Programmable Logic Controllers (PLC): Allow operators to set cutting lengths, speeds, and sequences digitally, facilitating quick changeovers and consistent output.

● Touchscreen Interfaces: Simplify machine operation by offering intuitive controls and real-time status monitoring.

● Automatic Tension Control: Maintains consistent paper tension during feeding to prevent wrinkles or misalignment.

● Safety Mechanisms: Include emergency stop buttons, safety guards, and sensors to protect operators.

These features ensure paper sheeter machines deliver high precision, efficiency, and safety, making them indispensable in modern paper processing.

Paper sheeter machines are versatile tools that handle various paper types. Choosing the right paper depends on your machine's capabilities and your production needs. Here’s a breakdown of common paper types suited for these machines:

Standard paper includes everyday office and printing papers such as bond paper, copier paper, and newsprint. These papers typically range from 40 to 120 gsm (grams per square meter). Paper sheeter machines easily cut these papers into uniform sheets for uses like brochures, flyers, or notebooks. Since standard paper is thin and flexible, most sheeters handle it without trouble.

Cardstock is thicker and heavier than standard paper, usually between 150 and 300 gsm. It’s common in business cards, postcards, and packaging inserts. Paper sheeter machines designed for thicker materials have stronger blades and adjustable feeding mechanisms to prevent jams or uneven cuts. Some machines offer specialized settings to handle the extra thickness smoothly, ensuring clean, precise edges.

Specialty papers include coated papers, textured papers, vellum, and metallic or glossy finishes. These papers often require careful handling because coatings can cause slipping or blade wear. Advanced paper sheeter machines come equipped with features like adjustable blade pressure, anti-static devices, and tension controls to manage these delicate materials. They allow businesses to produce premium-quality sheets for luxury prints, invitations, or art projects.

Synthetic papers, such as polypropylene, polyester films, or waterproof papers, are durable and resistant to tearing or moisture. These materials are used in labels, maps, or outdoor signage. Cutting synthetic sheets demands machines with robust blades, often rotary cutters, and adjustable speeds to avoid melting or fraying edges. Not all paper sheeter machines support synthetics, so verify compatibility before processing.

Paper sheeter machines vary widely in their capabilities. The machine's build, motor power, and feeding system all influence which paper types it can handle. For example, machines with higher motor power and robust feeding rollers can process thicker papers like cardstock or synthetic sheets without jamming. Conversely, lighter machines may only suit standard papers. Additionally, the maximum paper roll width and thickness supported by the machine dictate compatibility. Always check these specs before selecting a machine for your paper type.

Blades are crucial for clean, precise cuts. Different paper materials require different blade types and settings:

● Straight blades are common for standard and cardstock papers, providing sharp, straight cuts.

● Rotary blades excel at cutting synthetic materials or specialty papers, reducing edge fraying.

● Adjustable blade pressure helps accommodate paper thickness variations. Too much pressure can damage thin papers, while too little may cause incomplete cuts on thick sheets.

Blade sharpness also matters. Dull blades increase paper waste and reduce quality. Some machines offer automatic blade sharpening or easy blade replacement, which is valuable for maintaining performance.

The volume and speed of production impact the choice of machine and its compatibility with paper types. High-speed sheeters designed for large volumes may struggle with very thick or specialty papers unless specifically engineered for those materials. Slower machines allow more careful handling of delicate or coated papers, reducing the risk of damage. Matching production speed to paper type ensures consistent quality and minimal waste.

Paper sheeter machines boost production efficiency by automating the cutting process. They handle large rolls of paper and cut sheets at high speeds, much faster than manual methods. This automation reduces labor costs and speeds up workflows. Precision is another major benefit. These machines use advanced controls like servo motors and programmable logic controllers to cut sheets to exact sizes every time. Consistent sheet dimensions are vital for printing and packaging quality. Precise cuts also reduce rework, saving time and resources.

Using paper sheeter machines significantly cuts down paper waste. Manual cutting often leads to irregular sizes or damaged sheets, causing waste. Sheeter machines maintain uniform tension and blade sharpness, ensuring clean cuts without tearing or fraying. They can be programmed to optimize sheet sizes based on roll dimensions, minimizing leftover scraps. Less waste means lower material costs and a greener production process. Some machines even feature automatic waste collection systems, simplifying cleanup and improving workplace safety.

Consistency is key in paper processing. Paper sheeter machines deliver uniform sheets batch after batch, maintaining product quality. This uniformity is essential for downstream processes like printing, folding, or binding, where size variations can cause jams or misalignments. The machines' advanced sensors and feedback loops adjust cutting parameters in real time to handle variations in paper thickness or roll tension. This adaptability ensures each sheet meets strict quality standards, enhancing the final product's appearance and functionality.

Several manufacturers dominate the paper sheeter machine market, known for their quality, innovation, and reliability:

● BW Papersystems: Famous for high-speed, precise machines. Their equipment suits large-scale operations needing strict dimensional accuracy.

● Pasaban: Offers durable machines adaptable to coated, laminated, and specialty papers. Their models fit both small and large production volumes.

● Colter & Peterson: Known for dual-blade synchronous cutting systems. Their machines balance performance and affordability for mid-sized businesses.

● Vatan Makina: A global leader with installations in over 30 countries. Their machines handle high-volume orders with minimal downtime.

● Gaobao HighTop: A standout innovator offering automatic paper roll to sheet cutting machines. They combine precision, speed, and cost-effectiveness, making them popular worldwide.

● Hangzhou Depai Machinery Co., Ltd.: Provides compact, user-friendly machines ideal for small workshops.

● Kingsun Machinery: Specializes in servo-controlled machines for high-precision tasks, targeting luxury packaging and stationery sectors.

● CHM Machinery: Focuses on energy-efficient, high-speed sheeters optimized for standard and custom sheet sizes.

These brands have built reputations by delivering machines that meet diverse industry needs, from office supplies to heavy industrial applications.

Modern paper sheeter machines incorporate cutting-edge technology to enhance performance and usability:

● Servo Motor Controls: Allow precise speed and feed adjustments, resulting in cleaner cuts and less waste.

● Programmable Logic Controllers (PLC): Enable customizable cutting sequences and quick changeovers, improving production flexibility.

● Touchscreen Interfaces: Simplify operation with intuitive controls and real-time monitoring.

● Automatic Tension Control: Maintains consistent paper tension, preventing wrinkles and misfeeds.

● Advanced Blade Systems: Include rotary blades and automatic sharpening to handle various paper types efficiently.

● IoT Connectivity: Some machines now support remote monitoring and predictive maintenance, reducing downtime.

● Energy Efficiency: New models use less power while maintaining high output, lowering operational costs.

These innovations help manufacturers meet growing demands for speed, precision, and sustainability.

Manufacturers increasingly offer customizable paper sheeter machines to fit specific business needs:

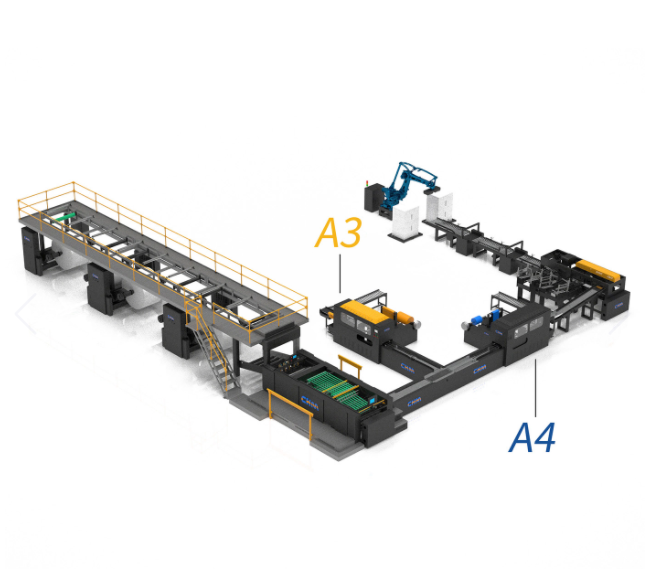

● Adjustable Cutting Lengths and Widths: Machines can be tailored to produce sheets in various sizes, including standard A4 or custom dimensions.

● Modular Designs: Allow businesses to upgrade or expand capabilities as production grows.

● Specialized Features: Such as anti-static devices for coated papers or reinforced rollers for thick cardstock.

● Integration Options: Machines can connect with upstream and downstream equipment for seamless production lines.

● Automation Levels: From manual to fully automatic models, enabling scalability from small startups to large enterprises.

Customization ensures companies get machines suited to their product range, volume, and budget, maximizing ROI.

Tip: When selecting a paper sheeter machine, prioritize manufacturers offering advanced automation, customization options, and reliable after-sales support to future-proof your investment.

Operating paper sheeter machines effectively ensures smooth production, high-quality output, and long machine life. Following best practices helps avoid downtime and costly repairs.

Routine maintenance is crucial. Schedule inspections to check blade sharpness, lubrication of moving parts, and roller conditions. Clean dust and paper debris to prevent jams or blade dulling. Replace worn components promptly. Regularly calibrate the machine to maintain cutting precision. Preventive maintenance reduces unexpected breakdowns and extends machine lifespan.

Well-trained operators improve safety and efficiency. Train staff on machine controls, adjustment settings, and troubleshooting common issues. Teach proper feeding techniques to avoid paper misalignment or jams. Emphasize the importance of monitoring blade condition and machine performance during runs. Skilled operators can spot problems early and maintain consistent output quality.

Safety is paramount when working with cutting machinery. Always use safety guards and emergency stop buttons. Require operators to wear protective gear like gloves and eye protection. Keep the work area clean and free of obstructions. Establish lockout/tagout procedures during maintenance or blade changes. Regularly review safety guidelines and conduct drills to reinforce safe practices.

Implement a maintenance checklist and operator training program to maximize your paper sheeter machine's performance, safety, and lifespan.

Paper sheeter machines efficiently transform large paper rolls into sheets, handling various types from standard to specialty papers. Future advancements will likely enhance precision and efficiency. When selecting a machine, consider features like automation and compatibility with paper types. Cheung Kong Machinery offers innovative paper sheeter machines that deliver precision and efficiency, meeting diverse industry needs and providing excellent value with advanced technology and customization options.

A: A paper sheeting machine can handle various types of paper, including standard office paper, cardstock, specialty papers, and synthetic materials, depending on the machine's specifications and blade settings.

A: A paper sheeting machine automates the cutting process, reducing labor costs and speeding up workflows. It uses advanced controls for precise cuts, ensuring consistent sheet dimensions and minimizing waste.

A: The blade type in a paper sheeting machine is crucial for clean, precise cuts. Different materials require specific blades, such as straight blades for standard papers and rotary blades for synthetics.

A: Paper sheeting machines equipped with adjustable blade pressure and tension controls can handle specialty papers like coated or textured materials, ensuring premium-quality sheets for luxury prints and art projects.

A: To ensure compatibility with synthetic materials, verify that your paper sheeting machine has robust blades, often rotary cutters, and adjustable speeds to avoid melting or fraying edges.