English

English- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English

Views: 0 Author: Site Editor Publish Time: 2025-09-14 Origin: Site

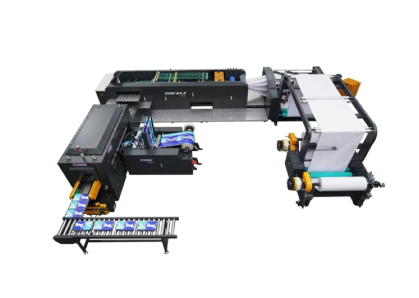

In the fast-paced printing industry, efficiency, precision, and consistency are essential for maintaining a competitive edge. Among the many tools that modern printing facilities rely on, the Copy Paper Cutting Machine stands out as a cornerstone of productivity. From small print shops to large-scale industrial operations, these machines have revolutionized the way paper is prepared, ensuring that businesses can meet growing demand while maintaining high standards of quality.

This article explores how copy paper cutting machines enhance productivity in the printing industry, detailing their evolution, features, benefits, and best practices for optimizing their use.

Copy paper may seem like a simple commodity, but preparing it for printing is a complex process. Paper must be cut to precise dimensions, stacked accurately, and handled efficiently to prevent waste or errors. Copy paper cutting machines automate these tasks, allowing operators to process large volumes of paper quickly and consistently.

In a modern printing facility, these machines are integral to the workflow. They ensure:

Precise sizing, so printed materials meet exact specifications.

Consistent stacking, facilitating smooth feeding into printing presses.

Time savings, by reducing manual labor and repetitive tasks.

By automating these essential steps, printing operations can maintain a steady production pace without sacrificing quality.

The journey of copy paper cutting machines reflects broader industrial trends. Early paper cutting relied on manual guillotine cutters, which were labor-intensive and prone to errors. With the advent of mechanical and semi-automatic machines, production capacity improved, and consistency increased.

Today, fully automated and high-speed digital machines dominate the industry. They feature programmable cutting sequences, hydraulic or pneumatic clamping systems, and advanced digital interfaces, all designed to maximize throughput and minimize human intervention. This evolution has directly contributed to increased productivity, allowing printing facilities to handle higher volumes of paper efficiently.

Modern copy paper cutting machines come with a range of features designed to enhance workflow efficiency:

Automatic feeding mechanisms reduce manual handling of paper stacks, enabling continuous operation and minimizing downtime between cuts.

Computerized control systems allow operators to program cutting sequences and dimensions accurately. This ensures that each sheet is cut to exact specifications, reducing material waste and rework.

Advanced cutting blades, often powered by hydraulic or servo systems, allow high-speed processing of thick stacks of paper. This capability significantly increases output compared to older machines.

Built-in safety guards, sensors, and emergency stops protect operators from potential hazards, reducing accidents while maintaining a smooth workflow.

Secure clamping systems ensure that paper stacks remain stable during cutting, eliminating errors caused by shifting sheets and further improving efficiency.

The adoption of modern copy paper cutting machines delivers several tangible benefits to printing businesses, helping them improve efficiency, quality, and overall workflow. These advantages make the machines indispensable for operations of any scale, from small print shops to large industrial facilities.

Increased Productivity – Automated cutting and feeding systems allow printing facilities to process large volumes of paper quickly and continuously. By minimizing manual handling and setup time, these machines reduce bottlenecks in the workflow and enable consistent, high-speed output. This efficiency is especially valuable during peak production periods, ensuring deadlines are met without compromising quality.

Enhanced Accuracy and Consistency – Modern machines feature digital controls and precise alignment systems that guarantee each cut meets exact specifications. This consistency reduces errors that can result in wasted material or rework, ensuring that every sheet meets the standards required for professional printing. Reliable accuracy also helps maintain the reputation of printing businesses among clients and partners.

Labor Optimization – Automation reduces the reliance on manual labor for repetitive cutting tasks. Operators can redirect their efforts toward higher-value activities, such as quality control, machine supervision, or finishing processes. This not only improves operational efficiency but also enhances employee satisfaction by reducing physically demanding and monotonous work.

Reduced Material Waste – Accurate cutting minimizes overages and scrap, leading to significant cost savings over time. Less waste also contributes to sustainable production practices, helping printing companies reduce their environmental footprint while making the most of raw materials.

Improved Safety – Built-in safety features such as blade guards, sensors, emergency stops, and automatic shut-off systems protect operators from accidents. Reduced risk of injury minimizes downtime caused by workplace incidents and fosters a safer, more productive working environment.

Scalability – High-speed and automated cutting machines can easily handle increased production demands without requiring a proportional increase in labor or resources. This makes them ideal for growing printing businesses, as they can expand capacity efficiently while maintaining quality and consistency.

Overall, these benefits highlight why modern copy paper cutting machines are essential for printing operations. By improving productivity, accuracy, labor efficiency, safety, and scalability, they provide a strong return on investment and help businesses stay competitive in a demanding industry.

To fully leverage the benefits of a copy paper cutting machine, printing facilities must integrate these machines thoughtfully into their overall workflow. Proper integration ensures maximum efficiency, reduces downtime, and maintains high-quality output throughout the production process.

Pre-Production Planning – Effective planning is the foundation of smooth operations. Printing facilities should determine paper sizes, stack quantities, and cutting specifications in advance. This allows operators to set up machines correctly and reduces delays caused by frequent adjustments. Planning also helps anticipate peak production periods, ensuring the machine operates at optimal capacity when demand is high.

Regular Maintenance – Maintaining the machine in top condition is crucial for reliable performance. Blades should be kept sharp, sensors and guides cleaned regularly, and routine inspections performed to identify and correct any mechanical issues. Consistent maintenance prevents unexpected breakdowns and ensures precise, consistent cuts, protecting both product quality and operational efficiency.

Operator Training – Skilled operators are key to maximizing machine performance. They must understand safety protocols, machine functions, and troubleshooting techniques to quickly address minor issues. Well-trained staff reduce errors, increase productivity, and enhance workplace safety.

Workflow Coordination – Aligning the cutting process with upstream (paper supply) and downstream (printing press) operations is essential to minimize idle time. Smooth coordination ensures a continuous flow of materials, reduces bottlenecks, and enhances overall production efficiency.

By implementing these practices, businesses can fully harness the potential of copy paper cutting machines, achieving streamlined production, reduced waste, and consistent, high-quality output.

The Copy Paper Cutting Machine is more than a simple tool; it is a productivity engine for the modern printing industry. By automating cutting processes, improving accuracy, enhancing safety, and reducing waste, these machines enable printing businesses to operate at peak efficiency.

For printing facilities looking to upgrade their equipment and boost productivity, Dong Guan Chun Hing Mechanical Technology Co., Ltd. offers advanced copy paper cutting solutions tailored to diverse production needs. Their expertise and innovative machinery can help your business take advantage of the latest advancements in paper cutting technology, ensuring efficiency, precision, and long-term growth.