English

English- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English

Views: 0 Author: Site Editor Publish Time: 2025-11-14 Origin: Site

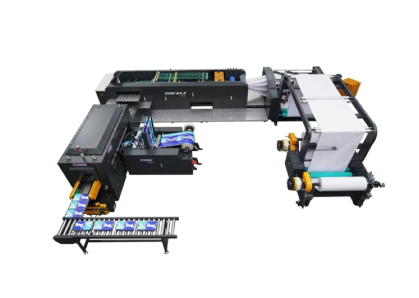

In today’s fast-paced printing industry, efficiency, precision, and speed are crucial for maintaining a competitive edge. One of the most essential tools for modern printing facilities is the high-speed copy paper cutting machine. These machines automate the cutting process, ensuring accurate cuts with minimal waste, boosting productivity, and reducing labor costs.

This article will explore the key features, benefits, and considerations when selecting a copy paper cutting machine for your business. You'll learn how these machines enhance workflow and help improve operational efficiency.

High-speed copy paper cutting machines are designed to automate one of the most time-consuming tasks in the printing process—cutting paper. The introduction of these machines has revolutionized paper processing in printing facilities. By eliminating the need for manual cutting, printing businesses can achieve faster turnaround times, reduce bottlenecks in production, and lower labor costs.

These machines are built for continuous operation, meaning they can run non-stop during peak production periods without any slowdown, which is essential when dealing with large print runs or tight deadlines. This increased efficiency means that printing companies can handle more orders, reduce delays, and improve overall output, making the business more competitive in the market.

For example, consider a busy print shop that handles hundreds of thousands of sheets of paper daily. With a high-speed copy paper cutting machine, the operator can load a stack of paper, and the machine will automatically feed, cut, and stack the paper with minimal intervention. This level of automation allows the operator to focus on other critical tasks, such as quality control or overseeing printing operations, further enhancing productivity.

The importance of precision in the printing industry cannot be overstated. Whether printing brochures, flyers, or high-end marketing materials, the final product must meet exact specifications. High-speed copy paper cutting machines offer exceptional precision that manual methods simply cannot match.

With digital interfaces and programmable settings, operators can input the exact dimensions needed for each print job. This capability ensures that every sheet of paper is cut to the same size, with no discrepancies, even when running high volumes of materials. Additionally, these machines provide repeatable, consistent results throughout the production process, reducing human error and minimizing the chances of mistakes.

For instance, printing companies that produce custom packaging or specialty printed materials require precise cuts to fit custom shapes or sizes. High-speed copy paper cutting machines with programmable controls and automated features are ideal for such applications, as they offer flawless results and help maintain a high standard of quality across every print job. CHM’s high-speed cutting machines provide precise cuts with high repeatability, ensuring that your output meets the highest standards every time.

One of the standout features of high-speed copy paper cutting machines is their ability to handle high volumes of paper efficiently. These machines are built to process large stacks of paper quickly, which is essential for high-volume printing environments. Whether your business deals with books, posters, or large-scale commercial printing, these machines can keep pace with demanding production schedules.

For instance, during peak periods such as holiday seasons or promotional campaigns, printing facilities often face a surge in demand. High-speed cutting machines allow these businesses to increase their output without needing to hire additional labor or compromise on the quality of the cuts. The machine's automated systems ensure that paper is processed quickly and consistently, keeping the printing line running smoothly.

| Feature | High-Speed Copy Paper Cutting Machine | Manual Cutting Methods |

|---|---|---|

| Speed | Fast, continuous operation | Slow, intermittent |

| Precision | High, programmable and repeatable | Prone to human error |

| Labor Costs | Reduced through automation | Requires manual labor |

| Production Flexibility | Handles large volumes and diverse paper types | Limited flexibility |

One of the primary reasons high-speed copy paper cutting machines are so efficient is their automated feeding system. These machines are designed to load, align, and cut paper automatically, minimizing the need for manual intervention. The automation of these processes reduces the risk of human error, enhances workflow, and increases throughput.

For businesses that operate on tight deadlines or require high-volume cuts, the automated feeding system is a game-changer. It ensures that paper stacks are fed into the machine smoothly and consistently, minimizing the risk of misfeeds or jams, which can cause delays in production. Furthermore, automated systems allow for uninterrupted operation, meaning the machine can run continuously for longer periods, increasing the overall output.

Additionally, some high-speed machines, like those from CHM, include advanced feeding systems that can automatically adjust to accommodate different paper sizes or weights, further increasing their versatility and functionality. This capability is essential for businesses that work with various types of materials and need a machine that can adapt to different cutting requirements.

Accuracy is paramount when cutting paper in a printing facility, and high-speed copy paper cutting machines deliver this precision through advanced digital controls. These machines are equipped with computer interfaces that allow operators to input precise cutting specifications. With a simple touch of a button, operators can set and save cutting parameters for various jobs, ensuring that every cut is consistent and meets the desired specifications.

Servo-driven motors and hydraulic systems power the cutting blades, providing smooth and precise operation, even when cutting through thicker stacks of paper. These advanced systems ensure that the machine delivers uniform cuts across large volumes of paper, making them ideal for businesses that require consistent quality for every print run.

The inclusion of digital displays and programmable memory makes these machines even more user-friendly, allowing operators to quickly set up jobs, monitor cutting progress, and make real-time adjustments if necessary.

Safety is always a top priority in any industrial operation, and copy paper cutting machines are no exception. With their powerful blades and high-speed operation, these machines require robust safety features to protect operators and reduce the risk of accidents. Modern high-speed machines are equipped with a range of built-in safety mechanisms, such as safety guards, emergency stop buttons, and sensors that prevent the machine from operating if the safety guard is not in place.

The safety features not only protect workers from potential injuries but also ensure that the machine operates smoothly and efficiently. For example, some machines have a soft clamp foot treadle that automatically locks the paper in place before cutting, reducing the risk of the paper slipping or shifting during the cutting process.

By investing in a machine with comprehensive safety features, businesses can create a safer working environment and ensure that operators feel confident when using the equipment.

High-speed copy paper cutting machines are designed to handle a wide variety of paper types, weights, and finishes. Whether cutting standard copy paper, thicker cardstock, or even laminated sheets, these machines can adapt to meet the specific needs of your printing business. This versatility allows businesses to cater to a broader range of customers and products without needing multiple cutting machines.

The ability to handle different paper sizes and finishes also means that printing businesses can take on a wider variety of projects, from creating high-end marketing materials to producing custom packaging. High-speed machines equipped with adjustable settings can switch between paper types quickly, allowing for more flexibility and reduced downtime between jobs.

The primary benefit of high-speed copy paper cutting machines is the increase in productivity they offer. By automating the cutting process and handling large volumes of paper, these machines can significantly increase output compared to manual methods.

Faster cutting cycles reduce the time it takes to complete a job, allowing businesses to take on more orders and complete them more efficiently. Additionally, since the machine can run for extended periods without the need for breaks, production can continue even during non-operational hours, maximizing throughput.

For instance, a printing facility that previously required several employees to manually cut paper stacks can now replace this with one machine that operates at high speed, boosting both output and profitability.

Another major benefit of using high-speed copy paper cutting machines is the reduction in material waste. The accuracy of these machines ensures that every cut is precise, minimizing overages and scrap material. As a result, printing businesses can make the most of their raw materials, reducing the costs associated with wasted paper.

For example, a machine that can make precise cuts consistently ensures that every sheet of paper is used to its fullest, which can lead to significant cost savings over time. Additionally, reduced waste means that businesses are contributing to more sustainable production practices, which is increasingly important to both customers and regulatory authorities.

| Benefit | High-Speed Copy Paper Cutting Machine | Manual Cutting Methods |

|---|---|---|

| Speed | Fast, continuous operation | Slow, intermittent |

| Precision | High, programmable and repeatable | Prone to human error |

| Labor Costs | Reduced through automation | Requires manual labor |

| Material Waste | Minimization of waste through accuracy | High, due to manual cuts |

While high-speed copy paper cutting machines require an initial investment, they can lead to significant long-term cost savings. These machines help reduce labor costs by automating repetitive tasks, and their precision reduces material waste, which cuts down on raw material expenses.

Moreover, the durability and low-maintenance design of these machines make them a smart investment. Their advanced components, such as long-lasting cutting blades and automated systems, reduce the need for frequent repairs and replacements, further lowering operational costs.

To get the most out of your high-speed copy paper cutting machine, it’s important to plan ahead. This involves determining paper sizes, cutting specifications, and stack quantities before starting the job. By setting clear expectations and ensuring the machine is configured correctly before production begins, businesses can optimize their workflow and avoid delays during the cutting process.

Advanced planning also helps businesses prepare for peak production periods. By organizing jobs in advance, operators can streamline the setup process and ensure that production remains efficient during busy times.

Routine maintenance is essential to keeping your high-speed copy paper cutting machine in top working condition. Regular tasks like cleaning the blades, checking for wear and tear, and replacing worn-out components can help extend the machine’s lifespan and ensure it operates smoothly.

By following the manufacturer’s recommended maintenance schedule, businesses can avoid unexpected breakdowns and maintain the quality and accuracy of the cuts. Regular maintenance also helps preserve the machine’s safety features, ensuring that it remains a safe and reliable tool for operators.

Operator training is critical to maximizing the efficiency of a high-speed copy paper cutting machine. Well-trained operators understand how to use the machine effectively, troubleshoot minor issues, and ensure the safety features are utilized properly. This helps reduce errors and increases the overall efficiency of the printing process.

In addition to training operators, coordinating the cutting process with other workflows, such as paper feeding and printing, ensures smooth production. Minimizing downtime between each stage of the process helps businesses maintain a steady production pace and avoid delays.

High-speed copy paper cutting machines are crucial for printing facilities seeking enhanced efficiency, precision, and safety. These machines can handle large paper volumes, deliver precise cuts, and minimize waste, improving overall production. By selecting the right machine, businesses can significantly increase productivity and reduce costs. CHM offers top-tier cutting machines designed to optimize printing operations, providing value through efficiency and reliability.

A: A high-speed copy paper cutting machine is designed to automate the cutting process, delivering precise and efficient cuts for large volumes of paper.

A: By automating the cutting process, a copy paper cutting machine reduces manual labor, increases output, and ensures consistent quality, leading to higher productivity.

A: A high-speed copy paper cutting machine offers faster, more accurate cuts, reduces material waste, and minimizes labor costs compared to manual methods.

A: Consider cutting volume, paper type compatibility, precision, and automation features to ensure the machine suits your production needs.

A: The cost of a high-speed copy paper cutting machine varies based on features, size, and brand. Generally, it’s a long-term investment that saves labor and material costs.

A: Key advantages include increased speed, precision, reduced material waste, and improved safety for operators in high-volume printing environments.