English

English- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English

Views: 0 Author: Site Editor Publish Time: 2025-09-19 Origin: Site

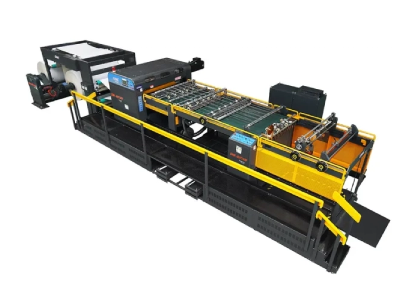

Sustainability is no longer just a buzzword in the printing and paper industry—it is a necessity. From reducing paper waste to optimizing production efficiency, every step in the paper manufacturing process impacts environmental sustainability. One often overlooked yet critical component in this process is the Copy Paper Cutting Machine. These machines play a pivotal role in producing paper products efficiently, minimizing waste, and ensuring precise dimensions, all of which are essential for sustainable operations.

In this article, we will explore how copy paper cutting machines contribute to sustainable paper production, examining their impact on resource utilization, energy efficiency, and long-term environmental benefits.

One of the primary ways copy paper cutting machines support sustainability is by reducing material waste. In paper production, any misalignment or inaccurate cut can result in off-cuts that are difficult to reuse. These remnants often end up as scrap, contributing to unnecessary paper waste.

Modern copy paper cutting machines utilize high-precision blades, laser alignment systems, and automated feeding mechanisms to ensure that every sheet is cut to exact dimensions. By improving accuracy:

The number of defective or misaligned sheets is minimized.

The amount of paper wasted per batch is significantly reduced.

Manufacturers can maximize the use of raw materials, reducing environmental impact.

In large-scale operations, where thousands of sheets are cut daily, even small improvements in accuracy translate to substantial reductions in waste over time.

Sustainable paper production begins with the careful use of raw materials. Copy paper cutting machines enable manufacturers to make the most of every paper roll or sheet:

Optimized Sheet Layouts: Advanced machines allow operators to program cutting patterns that make efficient use of sheet sizes, reducing leftover scraps.

Stack Cutting Capabilities: High-capacity machines can cut multiple sheets at once, ensuring uniformity and minimizing errors that would otherwise lead to wasted material.

Integration with Digital Planning: Many modern systems integrate with production planning software, allowing precise calculations of required sheet sizes before cutting.

By maximizing the utilization of each paper roll, copy paper cutting machines help reduce the demand for additional raw materials, contributing directly to resource conservation.

Energy consumption is a major concern in sustainable manufacturing. Copy paper cutting machines, particularly modern automated systems, play a role in reducing energy usage:

Reduced Manual Handling: Automation reduces the need for manual intervention, which not only improves safety but also reduces energy-intensive processes associated with handling miscuts or errors.

Optimized Motor Usage: Advanced machines use energy-efficient motors that consume less electricity without compromising cutting speed or precision.

Minimized Rework: Accurate cutting means fewer sheets need to be recut or reprocessed, saving both energy and labor.

Over time, the energy savings from efficient cutting contribute to a lower carbon footprint for the entire production process.

Paper products today are used not just for office supplies but also for packaging, labels, and promotional materials. Copy paper cutting machines support sustainable production in these areas by:

Creating Standardized Sizes: Consistent cuts reduce the need for additional trimming or modifications, which can generate extra waste.

Reducing Overproduction: Accurate cutting allows manufacturers to produce exactly what is needed for a job, limiting excess inventory and potential disposal of unused materials.

Facilitating Recycling: Even off-cuts from precise cutting are easier to recycle because they are uniform and free of irregular shapes.

By ensuring precision and minimizing scrap, cutting machines make it easier for companies to adopt environmentally friendly practices across their product lines.

Beyond paper itself, cutting operations can impact the use of chemicals and coatings:

Less Lamination Waste: Accurate cutting reduces the need for excess lamination or adhesive coatings.

Efficient Ink Usage: When paper is cut to precise dimensions for printing, ink coverage is optimized, reducing chemical waste.

Reduced Packaging Materials: Properly sized sheets decrease the need for additional packing materials to protect irregular or defective products during shipping.

The result is a holistic approach to sustainability, encompassing raw materials, energy, and auxiliary resources.

Sustainable production also includes worker safety and operational efficiency. Modern copy paper cutting machines incorporate advanced safety features that reduce accidents and minimize downtime:

Two-Hand Operation Controls: Prevent accidental blade contact.

Safety Shields and Sensors: Protect operators while maintaining high throughput.

Ergonomic Design: Reduces strain and fatigue, allowing workers to maintain efficiency over long shifts.

By safeguarding operators and reducing the risk of production interruptions, these machines contribute to a stable, sustainable workflow that conserves resources and maintains high productivity.

Sustainability in paper production often requires adaptability. Manufacturers deal with various paper weights, textures, and finishes depending on market demands. Copy paper cutting machines are designed to handle a wide range of specifications:

Multiple Sheet Handling: Ability to cut different thicknesses without compromising precision.

Adjustable Cutting Widths: Accommodates diverse product sizes with minimal setup changes.

Customizable Programs: Operators can store frequently used cutting patterns to reduce setup time and waste.

This versatility allows manufacturers to produce multiple product lines efficiently, without generating excess material loss.

Lean manufacturing principles—reducing waste, optimizing workflow, and improving quality—align naturally with sustainable practices. Copy paper cutting machines integrate seamlessly into these methodologies:

Automated Feedback Loops: Machines can detect and correct cutting errors immediately, preventing defective sheets from continuing through the production line.

Data Monitoring: Modern systems record cutting performance, helping managers identify opportunities to further reduce waste.

Just-in-Time Production: Precise cutting supports just-in-time printing and packaging, minimizing excess inventory.

Through integration with lean practices, cutting machines help manufacturers produce high-quality paper products while keeping resource use to a minimum.

Investing in a reliable copy paper cutting machine has financial as well as environmental benefits:

Reduced Raw Material Costs: Precision cutting reduces waste, lowering material expenditure.

Lower Energy Bills: Efficient machines consume less electricity.

Minimized Labor Costs: Automation allows operators to focus on higher-value tasks.

Fewer Returns and Reprints: Consistent quality reduces costly rework.

Sustainability doesn’t just protect the environment—it also improves the bottom line, creating a strong incentive for investment.

As the printing and paper industries evolve, several trends are shaping the next generation of copy paper cutting machines:

Smart Automation: AI-assisted cutting systems analyze patterns and optimize cutting sequences for minimal waste.

Eco-Friendly Materials: Machines constructed with recyclable components reduce their own environmental footprint.

Energy Recovery Systems: Some high-end models capture and reuse energy during operation.

Integration with Renewable Power: Cutting machines compatible with solar or green energy sources further reduce environmental impact.

These innovations ensure that paper production continues to meet sustainability goals while maintaining high productivity and quality standards.

The Copy Paper Cutting Machine is far more than a basic tool in paper manufacturing. It is a key enabler of sustainable production practices, from reducing waste and conserving energy to supporting lean workflows and enhancing product quality. By investing in modern, reliable cutting equipment, paper manufacturers can achieve both environmental responsibility and operational efficiency.

For companies looking to optimize their paper production process and adopt more sustainable practices, high-quality copy paper cutting machines are an essential component. Dong Guan Chun Hing Mechanical Technology Co., Ltd. offers advanced solutions designed for precision, efficiency, and long-term durability. Their expertise ensures that manufacturers can produce top-quality paper products while reducing waste and supporting sustainability initiatives. Reach out to them today to explore equipment options tailored to your production needs.